La version française de cet article n’est pas disponible pour le moment. Nous faisons tout notre possible pour la mettre en ligne dans les plus brefs délais. Merci de votre compréhension.

___

The LHC requires a variety of different types of magnets to direct the beams around its circular shape. Currently installed in the LHC’s interaction regions are 9.45-m-long double-aperture magnets of 2.8 T, manufactured by BNL for the RHIC. For HL-LHC, the interaction region magnets will be replaced by the recombination dipole D2, the longest of all the HL-LHC interaction region magnets. While also based on the same Nb-Ti technology as the previous magnets, the D2 magnets have a stronger field (4.5 T) and a wider aperture. Thanks to this upgrade, the “kick” given to the beams to bring them on the same path around IP1 and IP5 will increase from 28 to 35 tesla-metres (T·m), allowing space to install the crab cavities.

The HL-LHC will need four units of these magnets, plus two spares. These six magnets are deliverables of a collaboration agreement between INFN-Genova and CERN. The Italian institute was in charge of the design and construction of a short model and a full-size prototype, and is now carrying out the series production. The construction of the magnets took place at ASG Superconductors, Genova.

After the prototype magnet was delivered in late 2021, the team at CERN integrated it in 2022 into a cold mass with two prototype orbit correctors providing 5 T·m dipolar kicks. These correctors are based on a canted cosine theta technology, proposed in the late 60s, which has had an increase in attention in the past decade for its potential wide range of applications. A prototype of these correctors was developed at CERN, a second one in China under the helm of IHEP, and the series magnets are an in-kind contribution of China. These were then assembled alongside the D2 prototype in a 14-m-long cold mass at CERN.

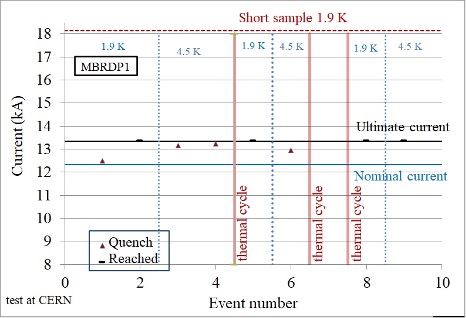

The team at CERN ran power tests of the magnets from late 2022 to June 2023. The prototype D2 reached its performance requirements at 1.9 K, corresponding to operation at 7 TeV in the HL-LHC plus a 0.5 TeV margin (the so-called ultimate current).

“We are extremely satisfied with the performances of the D2 prototype,” says Stefania Farinon, from INFN-Genova, who is in charge of the D2 collaboration agreement. “We are now finishing the construction of the first series unit at ASG, which will be delivered to CERN at the end of September.”

The powering of the correctors, already successfully tested in a standalone mode, showed an electrical issue in one of the circuits that will be analysed by the cold mass integration team. “Debugging these types of problems is one of the reasons to build prototype cold masses and not start directly with the series production,” says Herve Prin, in charge of the cold mass assembly in the Large Magnet Facility at CERN.

As pointed out by Arnaud Foussat, the project engineer in charge of the magnet and of the correctors from CERN: “These results are remarkable, also considering that this complex prototype cold mass, assembling parts from Italy, CERN and China, was manufactured in a period in which collaborations and activities were jeopardised by the pandemic.”